Titan's Twin-Pack Screen

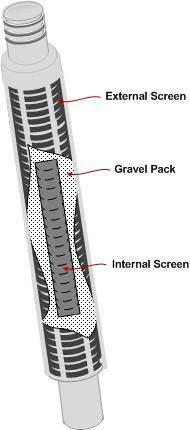

Many times unfavorable condition's make it difficult to use conventional gravel or filter pack. That's where Titan's Twin-Pack Screens can provide a timely and cost effective solution. Titan's Twin-Pack Screens utilize a screen within a screen and a uniform pack of filter sand in the annulus in between. This insures an effective gravel pack to prevent fine formation sediments from entering the well.

Because Twin-Pack Screens have their own gravel pack, you save a tremendous amount of time developing the well. Many times a smaller borehole can be drilled, thereby lowering drilling and installation costs. Environmental well application costs are further decreased since a smaller borehole means less hazardous material is removed which reduces disposal cost.

Titan's Twin-Pack Screens are available in a variety of screen sizes and slot widths to suit virtually any application. They can be Provided with the rounded prewashed silica sand installed or shipped minus the sand for sand packing at the job site.

Twin-Pack Screens can be constructed from a variety of PVC wall thicknesses or from HDPE (High Density Polyethylene). Twin-Pack Screens are produced in both plain end (for non-environmental applications) or with ASTM F480 Flush Joint Threads for applications where glued joints are not acceptable. Sizes from 1" through 8" are readily available, larger sizes can be made upon request.

As with all Titan products Twin-Pack Screens are cleaned to remove any manufacturing impurities. When used in environmental installations they are available in heat sealed heavy duty bags to ensure sanitary protection in transit.

Because Twin-Pack Screens have their own gravel pack, you save a tremendous amount of time developing the well. Many times a smaller borehole can be drilled, thereby lowering drilling and installation costs. Environmental well application costs are further decreased since a smaller borehole means less hazardous material is removed which reduces disposal cost.

Titan's Twin-Pack Screens are available in a variety of screen sizes and slot widths to suit virtually any application. They can be Provided with the rounded prewashed silica sand installed or shipped minus the sand for sand packing at the job site.

Twin-Pack Screens can be constructed from a variety of PVC wall thicknesses or from HDPE (High Density Polyethylene). Twin-Pack Screens are produced in both plain end (for non-environmental applications) or with ASTM F480 Flush Joint Threads for applications where glued joints are not acceptable. Sizes from 1" through 8" are readily available, larger sizes can be made upon request.

As with all Titan products Twin-Pack Screens are cleaned to remove any manufacturing impurities. When used in environmental installations they are available in heat sealed heavy duty bags to ensure sanitary protection in transit.